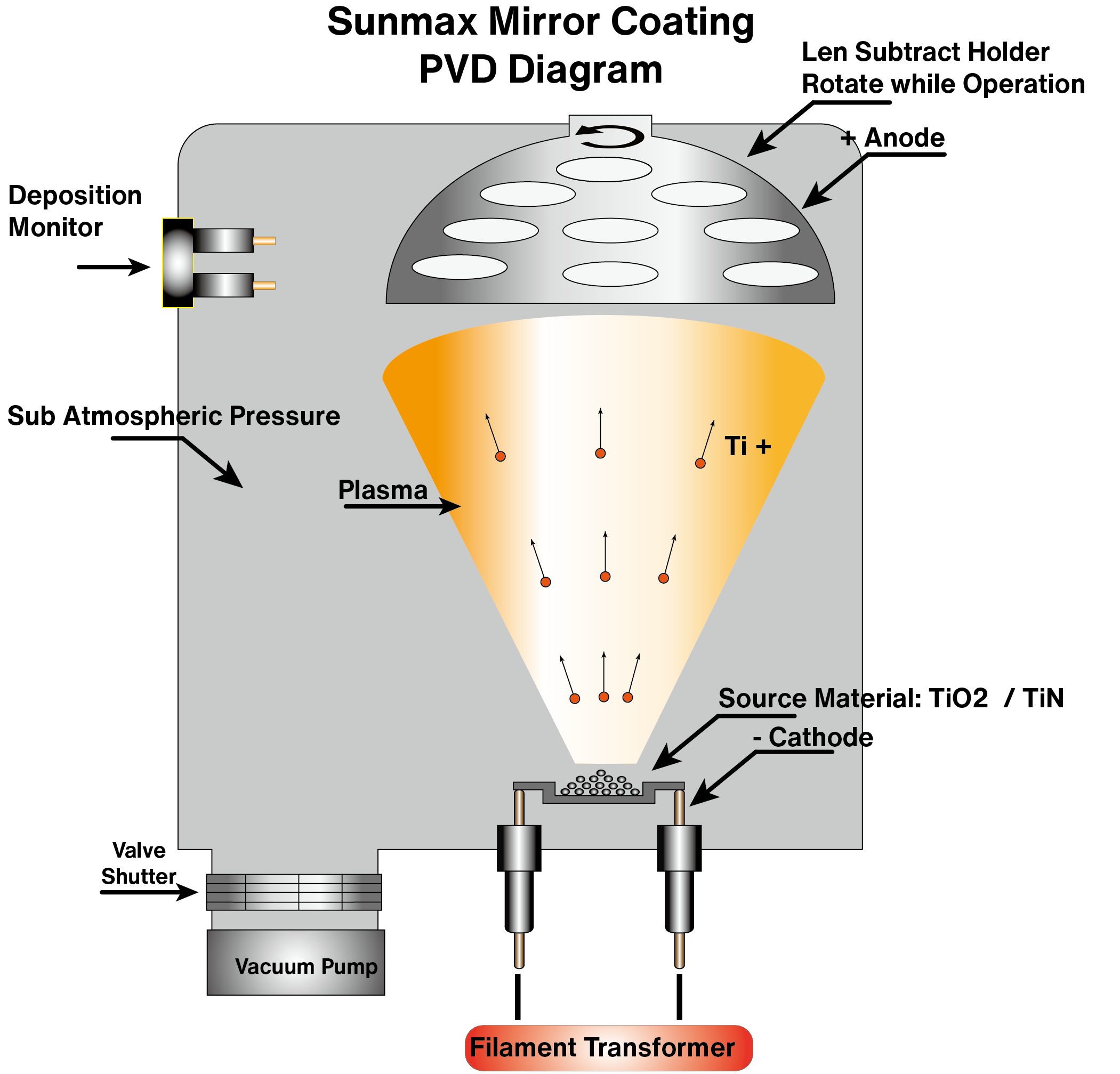

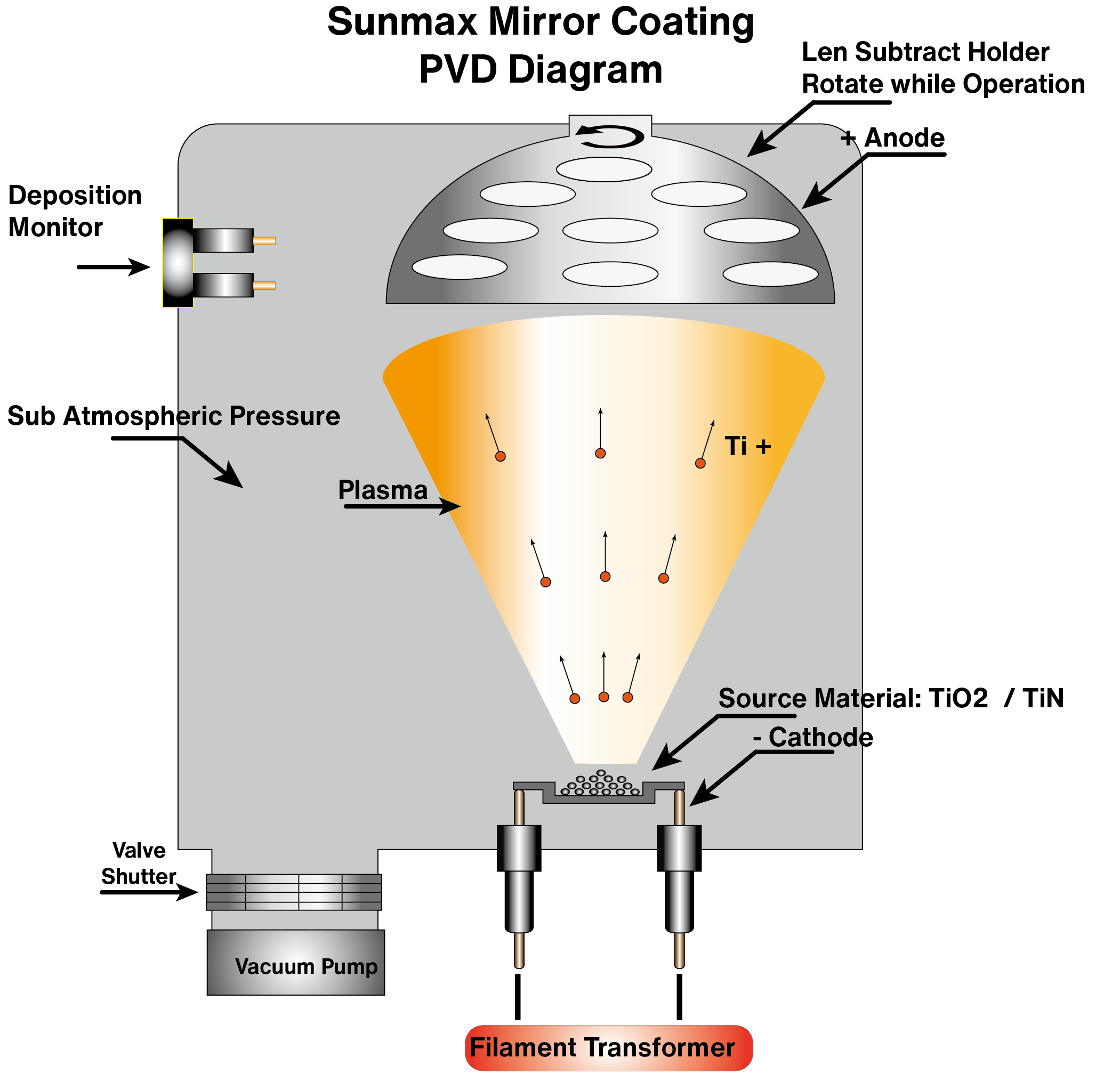

The len coating is applied with principle of Physical Vapor Deposition (PVD), that creates a layer thin film deposition on the lens with desired source material. The application of len including sports len, ski goggle len, polarized lens are commonly used in eyewear industries. Such application has been used for microchip, semiconductor device, durable protective film, cell phone screen, optical lens, solar panel, and many medical devices. All of the different application are done with hundred types of source material.

Picture: Sunmax Mirror Coating Physical Vapor Deposotion ( PVD )

The vacuum coating processes at vacuum (sub atmospheric pressure) environment, and an atomic or molecular condensable vapor source to deposit and to create a thin films deposition on surface of lens as a pure material or alloy composition coating. The thin film thickness is in the range of approximately 0.4 to 61 μm, depending on the request color of the mirror, and the function of coating.

By determining the wavelength of the color, Sunmax Optical Co., Ltd is able to custom coated desire color and function on the lens, and also developing new type of coating material with clients.

Whether the coating needs to be extreme thin, pure, durable, clean, blue light blocking, higher nanometer protection, Sunmax PVD provides the solution. We can always make new experiment type of coating with our clients.

The titanium is majority used and the chamber fill with oxygen for optical len, the oxygen become ionized, and the object become positive charge at the anode. The ionized charge titanium will dissipate within the chamber and moved to the positive charged subtract holder evenly.

The advantage of mirror coating delivers extra ultra violet protection for long hour sporter on the field and fashion element. The coating is made with “ dry “ condition, it is one of best way to minimize environment impact.

Whole Mirror Coating in blow picture

The vacuum coating machine uses cylinder shape len carrier to constant rotate in order to have each layer evenly coat fit with optical requirement. Each spot of the len, will be evenly coated. Each chamber requires 4~6 hours of coating time.

Diagram: Example of Whole Mirror Len Coating on 7 curvature sport len.

Sunmax Manufacture Comments: The Mirror Coating helps to bring several layers of protection on the len.

we can deposit 12 to 22 layers on the lens according to client request. The thicker the layers, the len can have

more control over the light and the sunshine. For extreme performance sport, such as extreme ski or running, long hours

of marathon, trithlon, and cycling. Several athlete would benefit from the 22 layers len of mirror coating.

Sunmax are always happy to make sample for clients to for such changes.

We also love to accept request from other optical product such as camera len, teleschope len, projector lens, for various purpose of

len mirror coating.

Please contact us via email: we will surely reply to you within one business day.

Gary Wang

- Sunmax Physical Vapor Deposition Diagram

- Len Subtract Holder