Each minute there are one million of plastic bottles thrown away, there is only 9 % of the bottle recycled and the rest of 273 million of bottle enters the landfill. The scenario applies the same to sunglasses.

99 % of sunglasses are difficult to be recycled; they are made without proper recycle assortment and material. Each minute there are only 1% of sunglasses recycled and 99 percent of thrown sunglasses going to landfill, and it is 4 million of sunglasses are stored in landfill each year.

In here, Sunmax Optical Co Ltd wants to repurpose the material of sunglasses. We introduce the PET (polyethylene terephthalate ) material for fashion sunglasses, prescription sunglasses and promotion sunglasses.

PET is the top three highly recyclable materials; it is the best choice for recycle plant. Due to the rising awareness of the environmental friendly, several new technologies and fashion giants improved technologies and look for better material to be reused, repurpose, and reduce. PET becomes one of the best choices to be remade as cloth, shampoo bottle, cloth, lotion bottle, and more. We believe sunglasses should join the trend recycle circle, to reduce waste and to make product more efficiently and more green. Here are ways for sunglasses to be involved.

For fashion sunglasses, Sunmax is able to make similar to acetate sunglasses panel. The PET panel can be made similar to the process of acetate sunglasses. It will both render high transparency, clean and durable appearance.

Please send us email for more specific manufacturing procedure.

Gary Wang, Product Deisgn: garywang@sunmaxglasses.com.tw

Karin Cheng, Manager : suncatta@ms17.hinet.net

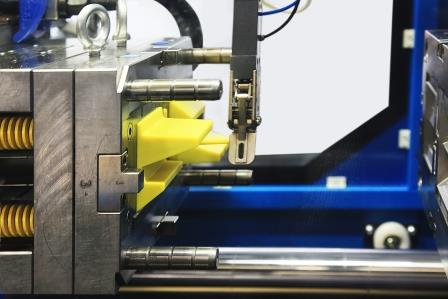

For mold injection sunglasses, when making in PET as injection material, we confirm the shape to be made in steel mold to be the right curvature shape according to the design. The PET delivers good control of shrinkage rate in 0.5 %. We are able to have the sunglasses to be made in clean and comfortable model. At the end the sunglasses can be recycled like all other bottle, and it will be remade again for another product.

Please send us email for more specific manufacturing procedure.

Gary Wang, Product Deisgn: garywang@sunmaxglasses.com.tw

Karin Cheng, Manager : suncatta@ms17.hinet.net

List of excellent traits for our PET material

1 High Translucent

The 86% percent of high clear appearance, suitable for clear frame sunglasses and clear temple design.

2 Impact Safety

Although PET material has less durability compared to PC (polycarbonate), it eventually achieve optical durability and stability in low temperature of -40 degree.

3 Shape Manipulation Advantage

Giving to PET material property, it can be shaped by sawing, mold cutting, laser cutting, gluing, including cold and hot bending , polishing, painting. Cold bending will not appear whitening. It will surely give more characteristic for sunglasses and fashion sunglasses.

4 High performance Thermal Properties

The precision mold injection is able to control shrinkage in 0.5 percent. More precise and abstract design is able to be made without much design revision.

| Material | Drying Temperatur : C | Drying in Hours |

| PET | 119 - 136 | 2-4.5 |

5 Environmentally Friendly

PET material is most capable product to be recycled.

6 High Chemical Resistance

Great material to resist acids, alkali, oils.

7 Low Flammability

Optical fire resistance, and non combatant, lowest smoke and no toxic gases.

8 Food and Skin Contact

The PET material meet with most of food regulation FDA or GBA.

In conclusion, there are several advantage of PET helps sunglasses to be recycle in the positive loop. PET is fully recyclable, variety of manufacturing process, injection molding shrinkage 0.5 %. For its help we could also manufacturing it with earth friendly responsibility. It helps the environment and global challenge that we have today.

Please contact us for specific information:

Gary Wang, Product Deisgn: garywang@sunmaxglasses.com.tw

Karin Cheng, Manager : suncatta@ms17.hinet.net

- PET material sunglasses